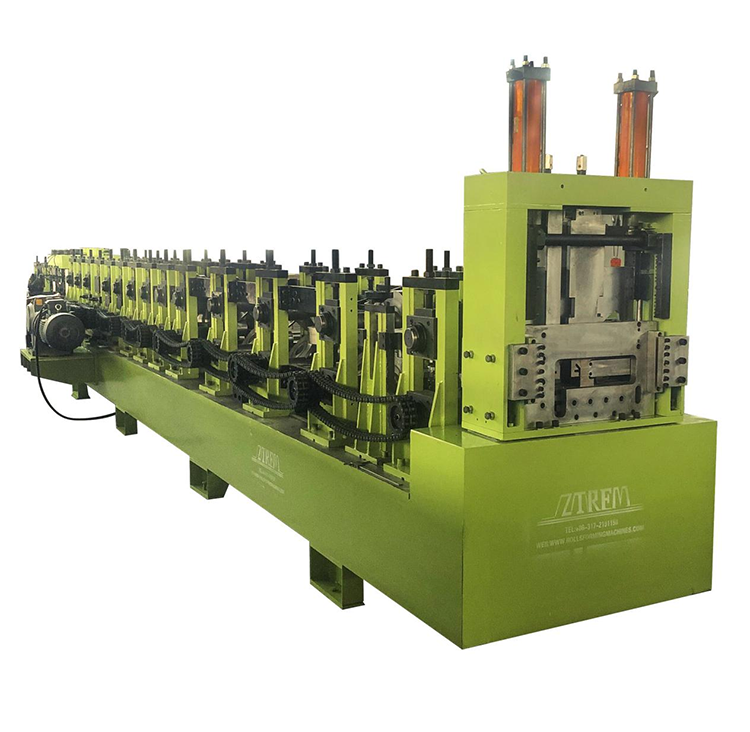

The strip is fed from the end of the machine, pressed into C purlin by various press rolls and sent out from the head. In the traditional process, after the C purlin is pressed and formed, it needs to be cut off by hand and then transported to the punching equipment to be punched according to the size required by the customer, which is not continuous and inefficient. After gradual improvement of the production process, we finally realized the automatic control of the whole process, which improved the production efficiency by leaps and bounds and increased the technical content and added value of the customer's equipment.

Main Features Of C Z Purlin Making Machine

The rolls are made of bearing steel (GR15), annealed after forging; the base is made of 500H steel; the lower five upper four leveling is used to ensure flatness; the secondary forming type is used to ensure the squareness and right angle of the product, and the size of the upper edge can be made; the thickness of the rolling material is 1.5mm-3mm (the thickness can also be designed according to user requirements).