The delivered four machines are respectively a roof panel roll forming machine, metal floor deck roll forming machine, two-in-one stud track roll forming machine and a hydraulic crimping curved machine. All equipment are controled by PLC computer system that would ensure the machine work both automatically and manually. Also hydraulic system is necessary for the roll formers to cut the finished sheet as per required lengths and quatities.

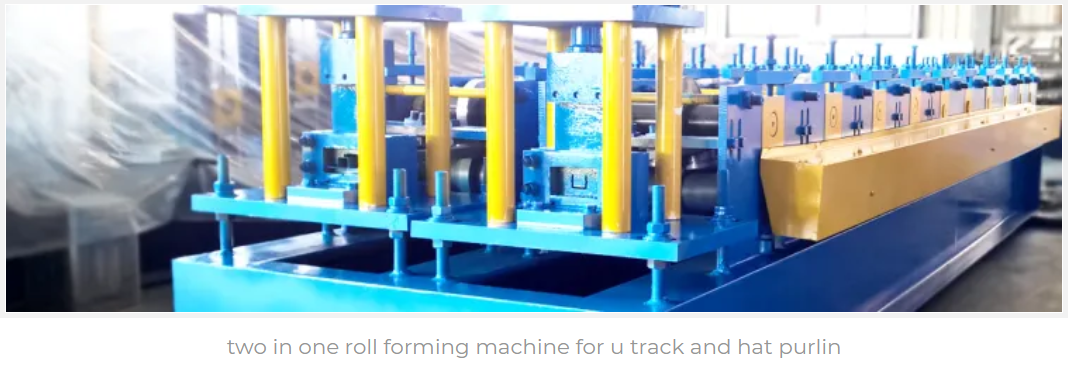

This two-in-one roll forming machine is among the delivery machineries. This roll former was designed and built to produce both hat purlins ( hat shaped roof trusses) and u trak with nothing to change. There is only one control system, transmission system and hydraulic system, but two profiles cannot be manufactured at the same time. With this machine, customers don’t have to order two roll forming machines which cost more money and larger area.

GEIT(ZTRFM) can provide all kinds of roll forming machines